What's The Difference Between Polyurethane And Polystyrene? A Deep Dive

Ever wondered what the heck is the difference between polyurethane and polystyrene? If you're scratching your head trying to figure out which material is best for your project, you're not alone. These two materials are often thrown around in conversations about insulation, packaging, and even furniture, but what makes them tick? Let's break it down!

Polyurethane and polystyrene might sound like alien words, but they're actually pretty common in our daily lives. From the foam in your couch to the insulation in your walls, these materials are everywhere. But here's the thing—they're not interchangeable, and understanding their differences can save you a lot of headaches.

This article is your ultimate guide to navigating the world of polyurethane and polystyrene. Whether you're a DIY enthusiast, a construction pro, or just someone curious about materials, you're in the right place. Let's dive in and unravel the mysteries of these two polymers!

- Familie Im Rampenlicht Wer Sind Mike Tysons Kinder Wirklich

- Enthllt Pearl Thusi Ehemann Alles Ber Ihre Beziehung

Table of Contents

- Introduction to Polyurethane and Polystyrene

- What Are Polyurethane and Polystyrene?

- Key Properties of Polyurethane and Polystyrene

- Common Applications

- Durability and Longevity

- Environmental Impact

- Cost Considerations

- Head-to-Head Comparison

- Maintenance Tips

- Final Thoughts

Introduction to Polyurethane and Polystyrene

So, why are polyurethane and polystyrene such big deals? Well, they're like the superheroes of the polymer world, each with their own unique powers. Polyurethane, for instance, is all about flexibility and strength, while polystyrene is more about being lightweight and cost-effective. But let's not get ahead of ourselves.

Both materials have their pros and cons, and choosing the right one depends on what you need it for. Are you looking for something that can withstand heavy use? Or do you need something that's easy to work with and won't break the bank? Stick around, and we'll help you figure it out.

What Are Polyurethane and Polystyrene?

Understanding Polyurethane

Polyurethane, or PU for short, is a type of polymer that's created by reacting a polyol with a diisocyanate or a polyisocyanate. Yeah, I know, it sounds like a science experiment, but trust me, it's worth it. This reaction produces a material that's super versatile and can be molded into almost anything you can think of.

- George Eads Alles Ber Den Csistar Karriere Amp Privatleben

- Alles Ber Die Mike Faist Gre Enthllt Seine Karriere

PU comes in different forms, including rigid foams, flexible foams, and even coatings. Its ability to adapt to various applications makes it a favorite in industries ranging from automotive to construction. It's like the Swiss Army knife of materials!

Getting to Know Polystyrene

On the other hand, we have polystyrene, or PS, which is a synthetic aromatic hydrocarbon polymer. Sounds fancy, right? Basically, it's made from styrene monomers that are polymerized to form a solid plastic. PS is known for being lightweight and easy to shape, making it a popular choice for packaging and insulation.

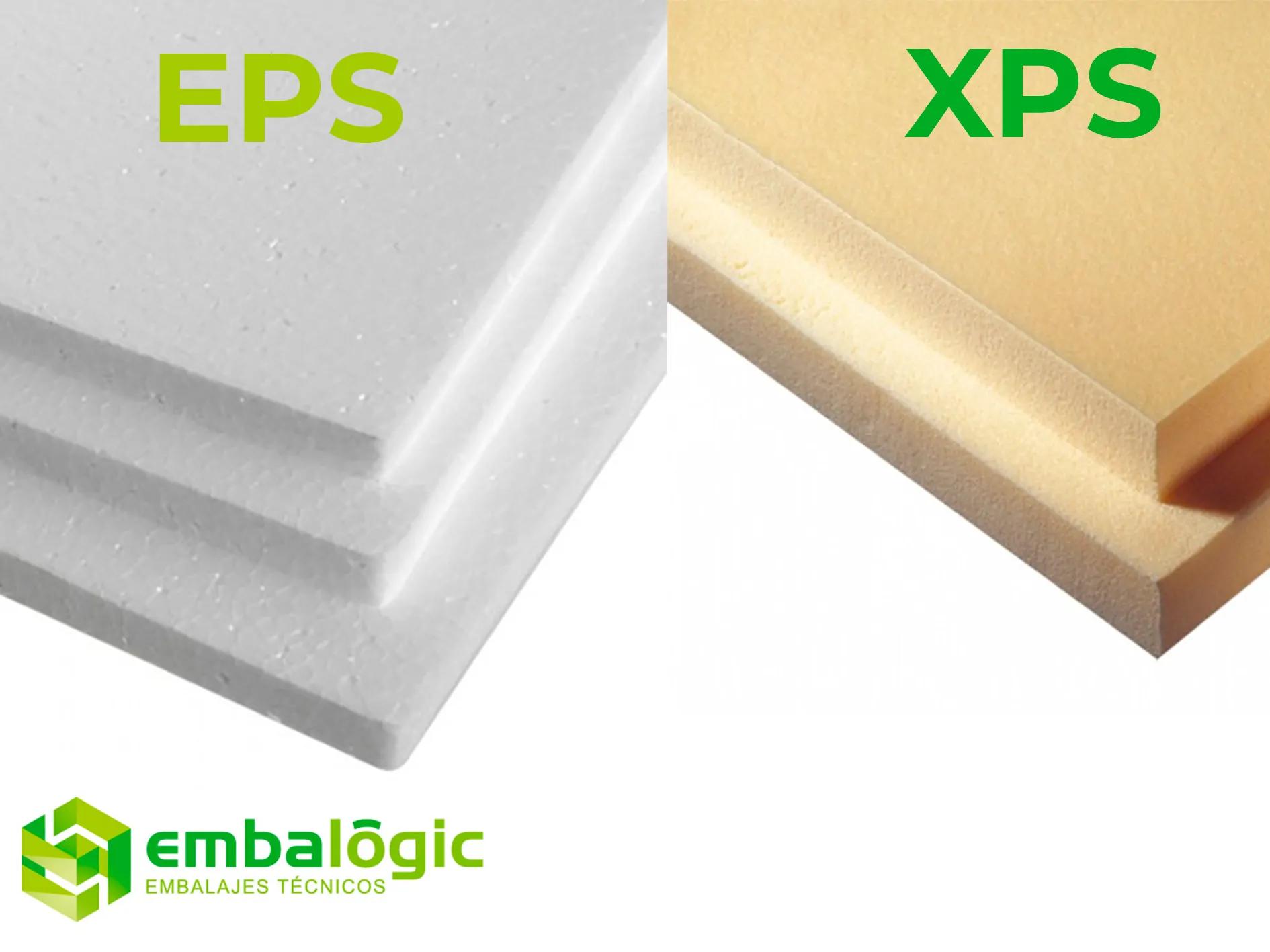

There are two main types of polystyrene: expanded polystyrene (EPS) and extruded polystyrene (XPS). EPS is the stuff you see in coffee cups and packaging peanuts, while XPS is often used in building insulation. Both have their own unique characteristics that make them suitable for different purposes.

Key Properties of Polyurethane and Polystyrene

Now that we know what these materials are, let's talk about what makes them tick. Here are some of the key properties of polyurethane and polystyrene:

- Polyurethane:

- High durability and resistance to wear and tear

- Excellent insulation properties

- Can be flexible or rigid depending on the formulation

- Resistant to chemicals and UV light

- Polystyrene:

- Lightweight and easy to shape

- Good thermal insulation properties

- Low cost compared to other materials

- Not as durable as polyurethane

As you can see, polyurethane and polystyrene have some overlapping properties, but they also have their own strengths and weaknesses. It's all about finding the right balance for your needs.

Common Applications

Polyurethane in Action

Polyurethane is used in a wide range of applications, from furniture and automotive parts to construction materials. Its versatility makes it a go-to choice for many industries. Here are some common uses:

- Furniture and bedding (foam cushions, mattresses)

- Automotive interiors (seat covers, dashboards)

- Building insulation (spray foam, rigid panels)

- Coatings and adhesives

Its ability to provide both comfort and protection is what makes polyurethane so popular. Whether you're lounging on your couch or driving your car, chances are you're surrounded by PU.

Polystyrene in Everyday Life

Polystyrene, on the other hand, is more commonly found in packaging and insulation. Its lightweight nature and affordability make it a practical choice for many businesses. Here are some examples:

- Packaging materials (peanuts, foam inserts)

- Food containers (cups, plates, clamshell containers)

- Building insulation (EPS and XPS boards)

- Disposable cutlery and plates

Polystyrene might not be as flashy as polyurethane, but it gets the job done when it comes to protecting products and keeping things cool or warm.

Durability and Longevity

When it comes to durability, polyurethane definitely takes the cake. It's built to last and can withstand heavy use without breaking down. Polystyrene, while durable in its own right, doesn't quite measure up in terms of longevity.

Think of it this way: if you're looking for something that's going to last for years without needing replacement, polyurethane is your best bet. But if you're working on a project that doesn't require long-term use, polystyrene might be the more practical choice.

Environmental Impact

Both polyurethane and polystyrene have environmental considerations that need to be taken into account. While they're both recyclable, the process can be tricky and isn't always widely available.

Polyurethane is often praised for its energy-saving properties, especially when used in insulation. However, its production can be energy-intensive and may involve harmful chemicals. Polystyrene, on the other hand, has faced criticism for its contribution to plastic pollution, particularly in the form of Styrofoam.

As consumers become more environmentally conscious, companies are exploring ways to make these materials more sustainable. Keep an eye out for innovations in this space!

Cost Considerations

Let's talk money. Polyurethane tends to be on the pricier side due to its advanced formulation and versatility. Polystyrene, however, is much more budget-friendly, making it a popular choice for cost-conscious businesses.

While the upfront cost of polyurethane might seem steep, it can save you money in the long run thanks to its durability and energy efficiency. Polystyrene, on the other hand, might need to be replaced more frequently, which could add up over time.

Head-to-Head Comparison

Now that we've covered the basics, let's put polyurethane and polystyrene head-to-head. Here's a quick rundown of how they stack up:

| Property | Polyurethane | Polystyrene |

|---|---|---|

| Durability | High | Medium |

| Cost | Higher | Lower |

| Insulation | Excellent | Good |

| Environmental Impact | Varies | Higher |

As you can see, polyurethane and polystyrene each have their own strengths and weaknesses. The key is to choose the material that best fits your needs and budget.

Maintenance Tips

Maintaining polyurethane and polystyrene is relatively straightforward, but there are a few things to keep in mind. For polyurethane, regular cleaning and protection from UV exposure can help extend its lifespan. Polystyrene, on the other hand, should be kept away from sharp objects and excessive heat to prevent damage.

If you're using these materials in a commercial setting, consider investing in protective coatings or covers to further enhance their durability. A little maintenance can go a long way in ensuring that your materials last as long as possible.

Final Thoughts

So, there you have it—the lowdown on polyurethane and polystyrene. Both materials have their own unique qualities that make them suitable for different applications. Whether you're building a house, designing furniture, or just trying to keep your coffee warm, there's a material out there that's perfect for the job.

We hope this article has helped you understand the difference between polyurethane and polystyrene a little better. Now it's your turn to take action! Leave a comment below and let us know which material you think is the better choice. And don't forget to share this article with your friends and family—they might find it just as useful as you did!

Article Recommendations

- Ist Kim So Hyun Vergeben Alles Ber Ihren Freund Aktuell Amp Gerchte

- George Eads Was Bringt 2024 Gerchte Karriere Mehr

Detail Author:

- Name : Ms. Catalina Mitchell PhD

- Username : adalberto82

- Email : bayer.diamond@hintz.net

- Birthdate : 1983-08-09

- Address : 252 Cassin Plaza New Hal, MT 28768-6065

- Phone : 1-616-586-3637

- Company : Prohaska, Johns and Botsford

- Job : Lay-Out Worker

- Bio : Cum omnis ut molestiae est provident sint necessitatibus. Qui et et aut velit est qui voluptatem. Et ea non molestiae. Nihil vel accusantium repellendus et repellendus quia.

Socials

facebook:

- url : https://facebook.com/ernsert

- username : ernsert

- bio : Odio illo veniam et aspernatur voluptas quis repudiandae.

- followers : 3380

- following : 2361

twitter:

- url : https://twitter.com/tatyanaernser

- username : tatyanaernser

- bio : Et saepe ab a nihil qui quam qui. Harum eveniet a soluta voluptatem. A eum nihil voluptatem velit quis inventore dolorum.

- followers : 3611

- following : 2913